Technology

Manufacturing support system

A complete set of devices to guarantee fail-free manufacturing and delivery process of our components.

More information

Processes under control

ERREKA Plastics invests in all needed equipment to help operators at all levels achieve the results for 0-defect manufacturing.

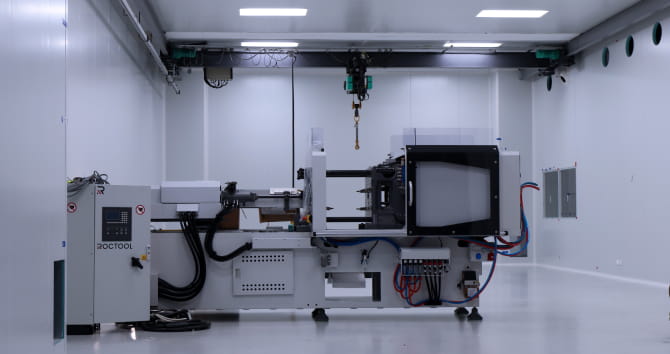

MES Manufacturing Execution System

The Manufacturing Execution System allows an accurate following and registering of the injection plant.

Unitary traceability

Laser marking is economically more convenient since there are no maintenance costs and no waste materials disposal costs.

CAQ Computer-aided Quality Assurance

Control of products’ relevant properties using computer systems. Quality control by ERREKA.

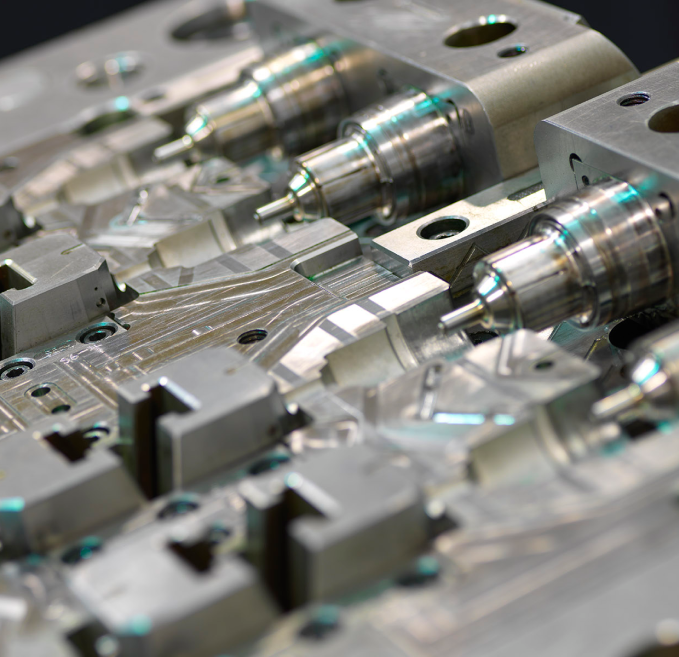

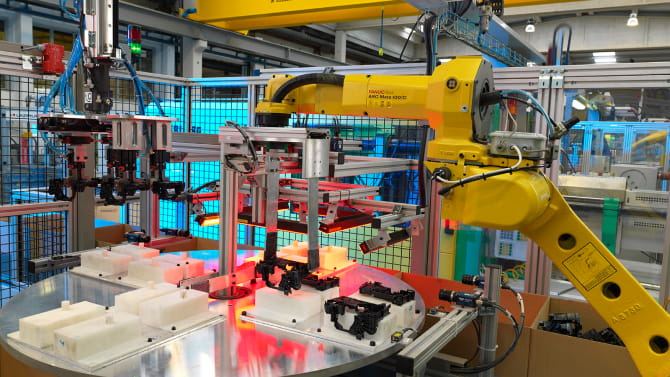

Automation development

ERREKA considers process automation to be a key point of injection and has an internal team to design and develop all automation projects.

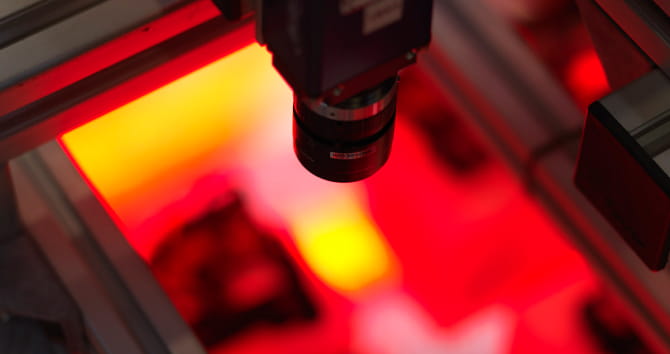

Artificial vision system

Artificial vision systems inside manufacturing cells for 100 % validation of the parts produced.

Metrology

Dimensional analysis and testing of products manufactured by plastic injection.

ERP

Fully digitised process starting from the client’s order to the goods delivery notes to the client.